Response to

Climate Change

Approach to Addressing Climate Change

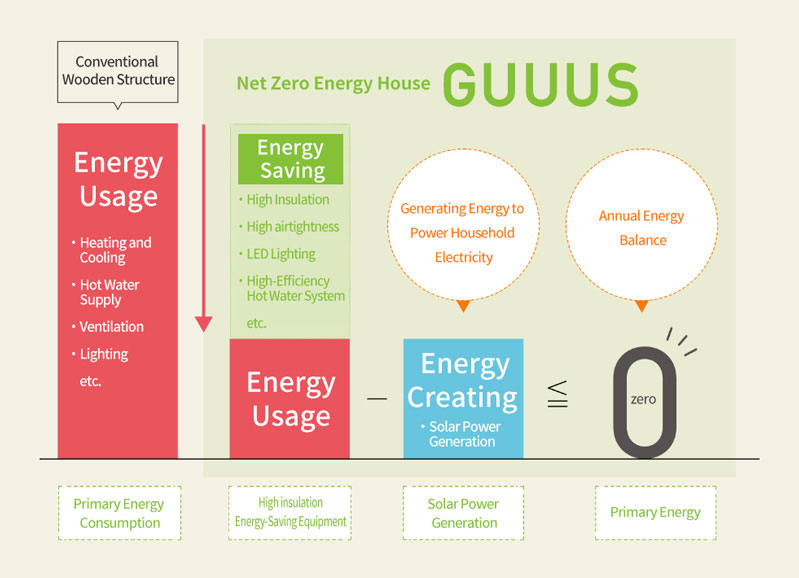

Our group, based in Hokkaido, has been engaged in home building while coexisting with the natural environment. We actively promote the reduction of fossil fuel energy consumption in ordinary households and the use of renewable energy through our proactive expansion of ZEH (Net Zero Energy House). Moving forward, we will continue to contribute to the spread of homes that are gentle to both the earth and its inhabitants by leveraging our accumulated know-how and new technologies.

Efforts to Address Climate Change

Our group is dedicated to fostering a decarbonized society through our business initiatives. We are promoting the sale of ZEH (Net Zero Energy Houses). This initiative is primarily implemented through our "GUUUS" housing products in the Tohoku region.

We will continue our efforts to provide homes that are both comfortable for customers and environmentally friendly.

Since November 2021, we have been promoting modular housing construction, and our main factory in Tomakomai has been operational since February 2022.By promoting modular home construction, we expect to reduce the use of on-site fuel and greenhouse gas emissions.

We plan to expand the product rollout area and further contribute to reducing environmental impact.

We also educate our employees on the global situation regarding climate change, including sharing information to enhance their awareness and response to climate change.

Quantitative Data

Initiatives for a Recycling-oriented Society

Approach to a Recycling-oriented Society

Our group company is committed to reducing industrial waste and promoting recycling. In addition to minimizing waste generated at construction sites, we strive to develop business processes that produce less waste by encouraging modular home construction.

Reducing Waste Generation

In November 2021, we constructed a modular home assembly factory in Tomakomai, which became fully operational in February 2022. By modularizing the wood needed for construction in the factory and transporting it to construction sites, we can reduce waste generation by approximately 60-70% compared to traditional on-site processing and assembly. Moreover, we plan to use wood offcuts from the factory to make furniture and further promote resource efficiency. We ensure waste separation at construction sites by displaying plates detailing sorting methods and maintain strict waste separation with our partner companies. We also prioritize choosing recycling-capable contractors for industrial waste disposal to reduce the final disposal amount of waste.

Management of Chemical Substances

Approach to Chemical Substance Management

To prevent environmental impact and health issues related to chemical substances, our group uses building materials with the highest formaldehyde emission standard, F☆☆☆☆ (Four-star), in all our construction projects.